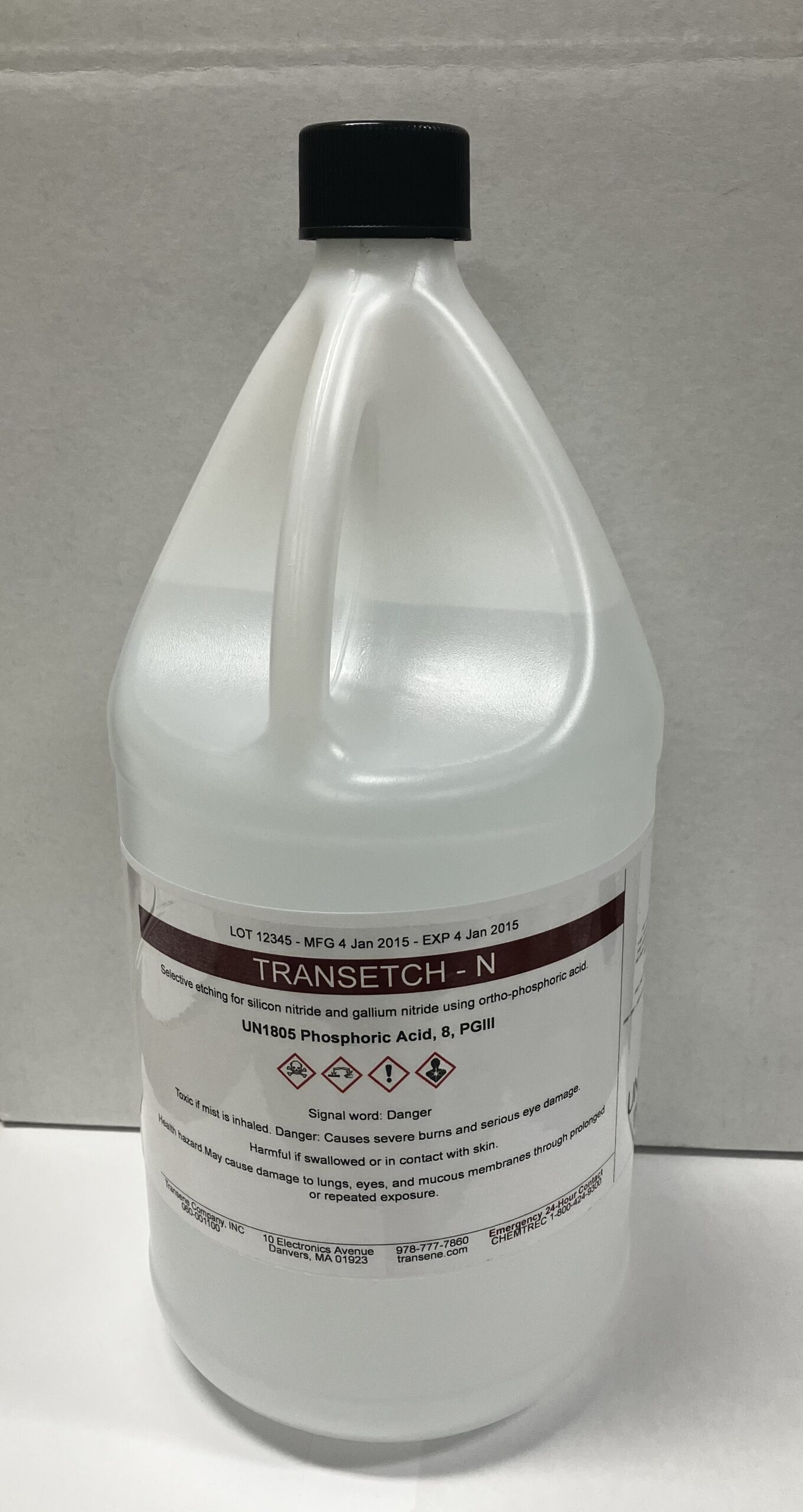

| TRANSETCH-N |  |

Selective Etchant for Gallium Nitride, Silicon Nitride or Aluminum Oxide Films

Fast and Controllable Etching of Silicon Nitride ( Si3N4 ), Galium Nitride ( GaN ), or Aluminum Oxide ( Al2O3 ) Films in New Semiconductor Technology

UNIQUE ADVANTAGES

- Convenient, ready to use.

- Selective, etches gallium nitride, silicon nitride or aluminum oxide films.

- Re-usable, does not weaken with use.

- Produces no noxious fumes, requires no hoods or venting.

- Virtually eliminates over-etching and under-cutting.

- Ensures successful planar passivation of silicon semiconductor devices.

TRANSETCH – N

DESCRIPTION

TRANSETCH-N is a purified reagent, derived from ortho-phosphoric acid, which selectively etches silicon nitride or aluminum oxide in the presence of silicon dioxide or silicon. When used as directed, it produces openings in these films with a degree of resolution comparable to the best obtainable with SiO2 in conventional planar technology, but with essentially no effect on exposed silicon or silicon dioxide surfaces. The photoresist materials, processes and equipment used in conventional etching operations are retained, and the additional equipment required is minimal and inexpensive. Note: Many photoresists may not be able to withstand the recommended operating temperature of Transech N. Consult your resist manufacturer before proceeding.

Transetch-N contains no fluorides. Unlike etchants based on fluoride chemistry, TRANSETCH-N produces minimal undercutting and therefore provides a wide margin of safety in the selection of etching times.

Transetch-N is stable and long-lived. The only attention which it may require in use is the addition of small amounts of water to replace that lost through evaporation.

PROPERTIES OF TRANSENE TRANSETCH-N

| How do I increase the etch rate? | 1. The rate will approximately double with every 10°C increase in temperature. 2. Increase the rate of stirring or agitation. |

||||||||||

| How do I reduce the etch rate? | Adding 1 part deionized water to 2 parts etchant will reduce the etch rate approximately 50%. | ||||||||||

| Do I need to dilute the etchant? | No, it is ready to use. | ||||||||||

| How do I reduce undercutting? | Increase the rate of stirring or agitation. | ||||||||||

| Appearance | Clear, colorless, syrupy | ||||||||||

| pH | Strongly acidic | ||||||||||

| Etch Rate at 178-180 °C |

|

||||||||||

| Etch Capacity (rate declines at ~70%) | 65 g/gallon | ||||||||||

| Shelf Life | 1 year | ||||||||||

| Storage Conditions | Ambient | ||||||||||

| Filtration | 1 um | ||||||||||

| Recommended Operating Temperatures | 178-180 oC | ||||||||||

| Rinse | Deionized water | ||||||||||

| Photoresist Recommendations | SiO2, HARE SQ (SU-8 type) | ||||||||||

| Select Compatible Materials | Glass, Au, Ni, Cu

See https://transene.com/etch-compatibility/ for more details. |

||||||||||

| Select Incompatible Materials | Al | ||||||||||

| Compatible Plastics | HDPE, PP, Teflon, PFA, PVC | ||||||||||

| Country of Origin | USA | ||||||||||

| Availability | 1-2 days | ||||||||||

| Available Sizes | Quart, Gallon, 5 Gallon, 55 Gallon | ||||||||||

| Packaging | HDPE | ||||||||||

| Packing | 4 gallons/case | ||||||||||

| Isotropy | Isotropic | ||||||||||

| Incompatible Chemicals | Strong bases | ||||||||||

| Additional Information | — |

APPLICATION:

TRANSETCH-N is employed in the new technology for surface passivation of semiconductor devices based upon the use of deposited Si3N4, GaN and Al2O3 films. This technology leads to high quality and reliability of semiconductor products and is particularly helpful in stabilizing MOS and MIS devices. Inversion layers and ion migration are virtually eliminated: leakage currents approach theory; and surface states are notably controlled.

INSTRUCTIONS:

TRANSETCH-N works best with a suitably etched layer of deposited SiO2 serving as the mask for the deposited film. The SiO2 layer is most conveniently applied immediately after the deposition of the passivating film. A thickness of 1000 Å is usually quite adequate for this purpose.

Conventional processes are employed to produce the image of the desired opening in the photoresist and in the deposited SiO2 layer. The photoresist is then removed with a chromic acid-sulfuric acid stripper.

The stripped and rinsed slices are then placed in boiling TRANSETCH-N for a period of time which allows one minute for each 100 Å of deposited film thickness. Water rinsing removes all traces of etchant.

NOTE: It is important that the boiling point of TRANSETCH-N be maintained at 180 °C. This generally requires that evaporative loss of water be minimized by the use of proper apparatus. Small amounts of distilled water may be added from time to time to ensure that the temperature of TRANSETCH-N does not exceed 180 °C.