| Gold Etchants |

Gold Etchant TFA |

for Microelectronics Circuits Selective etchants for gold, compatible with negative and positive photoresists-used in thin film microelectronics to develop circuit elements.

- Etching readily controlled with minimum undercutting — provides excellent definition.

- Room-temperature operated.

- Uniform etch rates

- Economical

- Gold Etchants TFA, GE-8148, GE-8110, and GE-8111 are available in glass or plastic packaging depending on shipment method

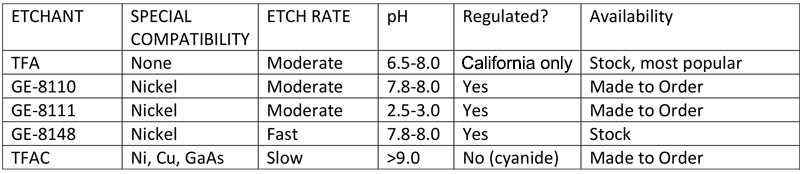

GOLD ETCHANT COMPARISON

Literature Citation Referencing Application of Gold Etchant TFA

GOLD ETCHANT TFA and GOLD ETCHANT GE-8148

DESCRIPTION: These thin film etchants are used to obtain selective etching of gold in the photo fabrication of microelectronic circuits. Used in conjunction with photoresist technology, these etchants form precise electrodes and resistor patterns in thin films prepared on alumina and other substrates. High purity, low sodium and 0.2 micron filtration for semiconductor and microelectronics applications. Gold Etchant TFA – Cyanide free for standard applications. GE-8148 – Cyanide free, no attack of nickel films.

PROPERTIES OF TRANSENE GOLD ETCHANT TFA

| How do I increase the etch rate? | 1. The rate will approximately double with every 10°C increase in temperature. 2. Increase the rate of stirring or agitation. |

| How do I reduce the etch rate? | Adding 1 part deionized water to 2 parts etchant will reduce the etch rate approximately 50%. |

| Do I need to dilute the etchant? | No, it is ready to use. |

| How do I reduce undercutting? | Increase the rate of stirring or agitation. |

| Appearance | Amber-brown |

| pH | 6.5-8.0 |

| Etch Rate at 25°C | 28 Å/sec. |

| Etch Capacity (rate declines at ~70%) | 65 g/gallon |

| Shelf Life | 1 year |

| Storage Conditions | Ambient |

| Filtration | 1 um |

| Recommended Operating Temperatures | 20-80oC (30-40oC most common) |

| Rinse | Deionized water; may be followed with alcohol rinse followed with alcohol rinse if dark residue remains. |

| Photoresist Recommendations | KLT6000 Series, KLT 5300 Series, HARE SQ (SU-8 type), TRANSIST, or PKP-308PI |

| Select Compatible Materials | Cr, Si, NiCr, Ti, Ti-W

See https://transene.com/etch-compatibility/ for more details. |

| Select Incompatible Materials | Ni, Cu, Al, Ag, GaAs, Ge |

| Compatible Plastics | HDPE, PP, Teflon, PFA, PVC |

| Country of Origin | USA |

| Availability | 1-2 days |

| Available Sizes | Quart, Gallon, 5 Gallon, 55 Gallon |

| Packaging | HDPE |

| Packing | 4 gallons/case |

| Isotropy | Isotropic |

| Incompatible Chemicals | — |

| Additional Information | — |

Max. Impurity (ppm, Gold Etch TFA)

| Sodium ( Na) | 40 |

| Chlorine & Bromides (Cl) | 100 |

| Lead (Pb) | 5 |

| Iron (Fe) | 3 |

| Sulfur (as sulfates) | 50 |

| Phosphorous (as phosphates in TFA) | 10 |

PROPERTIES OF TRANSENE GOLD ETCHANT GE-8148

| How do I increase the etch rate? | 1. The rate will approximately double with every 10°C increase in temperature. 2. Increase the rate of stirring or agitation. |

| How do I reduce the etch rate? | Adding 1 part deionized water to 2 parts etchant will reduce the etch rate approximately 50%. |

| Do I need to dilute the etchant? | No, it is ready to use. |

| How do I reduce undercutting? | Increase the rate of stirring or agitation. |

| Appearance | Amber-brown |

| pH | 7.8-8.2 |

| Etch Rate at 25°C | 50 Å/sec. |

| Etch Capacity (rate declines at ~70%) | 65 g/gallon |

| Shelf Life | 1 year |

| Storage Conditions | Ambient |

| Filtration | 1 um |

| Recommended Operating Temperatures | 20-80oC (30-40oC most common) |

| Rinse | Deionized water; may be followed with alcohol rinse followed with alcohol rinse if dark residue remains. |

| Photoresist Recommendations | KLT6000 Series, KLT 5300 Series, HARE SQ (SU-8 type), TRANSIST, or PKP-308PI |

| Select Compatible Materials | SiO2, Cr, NiCr, Ni, Ti, Ti-W

See https://transene.com/etch-compatibility/ for more details. |

| Select Incompatible Materials | Al, Cu, GaAs, Ag |

| Compatible Plastics | HDPE, PP, Teflon, PFA, PVC |

| Country of Origin | USA |

| Availability | 1-2 days |

| Available Sizes | Quart, Gallon, 5 Gallon, 55 Gallon |

| Packaging | HDPE |

| Packing | 4 gallons/case |

| Isotropy | Isotropic |

| Incompatible Chemicals | — |

| Additional Information | — |

Max. Impurity (ppm, Gold Etch TFA)

| Sodium ( Na) | 40 |

| Chlorine & Bromides (Cl) | 100 |

| Lead (Pb) | 5 |

| Iron (Fe) | 3 |

| Sulfur (as sulfates) | 50 |

| Phosphorous (as phosphates in TFA) | 10 |

GOLD ETCHANT GE-8110 GE-8111 GE-8110 and GE-8111 Gold Etchants are etching solutions designed specifically for etching thin films of gold in the fabrication of semiconductor devices and thin film microelectronics. The solutions are based on potassium iodide and iodine ( KI/I2) chemistry and do not contain cyanide. They are compatible with both positive and negative photoresist materials, giving controllable line definition. GE-8110 is buffered to approximately pH 8.0 while GE-8111 is acidic with a lower solids content and is a slower acting etching solution. Both etchants should be used at room temperature in a well-ventilated area. Physical and Chemical Properties: Appearance and odor: dark brown liquid with iodine vapor odor.

| GE-8110 | GE-8111 | |

| pH (20 °C) | 7.9 ± 0.1 | 2.5 ± 0.1 |

| Density ( 20 °C) | 1.33 ± 0.01 | 1.15 ± 0.01 |

| Etch Rate ( 30 °C) | 20Å/sec | 30Å/sec |

REAGENT GRADE CHEMICAL

| IMPURITY | SPEC. PPM (MAX) |

| MAX-IMPURITY PPM | |

| Sodium ( Na) | 40 |

| Chlorine & Bromides ( Cl) | 100 |

| Lead (Pb) | 5 |

| Iron (Fe) | 3 |

| Sulfur (as sulfates) | 50 |

Storage and Handling Store at room temperature away from sunlight. Keep container sealed when not in use. Iodine vapor can irritate the eyes severely. Open in ventilated areas. In case of contact with eyes or skin, wash with plenty of water (or soapy water for skin), and consult a physician if irritation persists.

GOLD ETCHANT TFAC FOR INTERMETALLIC SUBSTRATES

DESCRIPTION: Gold Etchant TFAC is a selective etchant for the preparation of microelectronic circuits on gallium arsenide, gallium phosphide, and other intermetallic semiconductor compounds. Gold Etchant TFAC provides excellent definition with minimal undercutting. Uniform etch rates are obtained with this cyanide based etchant. Gold Etchant TFAC strips gold from copper, brass, bronze, nickel, and other non-ferrous metals (except silver). Gold Etch TFAC is compatible with aluminum.

PROPERTIES OF TRANSENE GOLD ETCHANT TFAC FOR INTERMETALLIC SUBSTRATES

| How do I increase the etch rate? | 1. The rate will approximately double with every 10°C increase in temperature. 2. Increase the rate of stirring or agitation. |

| How do I reduce the etch rate? | Adding 1 part deionized water to 2 parts etchant will reduce the etch rate approximately 50%. |

| Do I need to dilute the etchant? | Dissolve 4 oz powder in enough water to yield 1.9 L or 8 oz to make 1 gallon. |

| How do I reduce undercutting? | Increase the rate of stirring or agitation. |

| Appearance | Solids mixture; white to off-white |

| pH | Alkaline when dissolved |

| Etch Rate at 60°C | 30 Å/sec. |

| Etch Capacity (rate declines at ~70%) | 90 g/gallon |

| Shelf Life | 1 year; 4-6 weeks when dissolved |

| Storage Conditions | Ambient |

| Filtration | Not applicable |

| Recommended Operating Temperatures | 40-60 oC |

| Rinse | Deionized water |

| Photoresist Recommendations | PKP-308PI or HARE SQ (SU-8 type) |

| Select Compatible Materials | GaAs, Si, Ni, Al

See https://transene.com/etch-compatibility/ for more details. |

| Select Incompatible Materials | SiO2 |

| Compatible Plastics | HDPE, PP, Teflon, PFA, PVC |

| Country of Origin | USA |

| Availability | 1-2 days |

| Available Sizes | 4 oz bottle, 8 oz bottle |

| Packaging | HDPE |

| Packing | 1 bottle/case |

| Isotropy | Isotropic |

| Incompatible Chemicals | Acids |

| Additional Information | Cyanide chemistry |

APPLICATION: Warm water to approximately 50 °C to aid dissolution. Add 8oz Gold Etchant TFAC powder per gallon deionized water. Etch the conductor pattern to remove gold; etch time depends on thickness. Spent etchant should be saved for gold reclamation. Disposal: Segregate solution. Cyanide should be handled carefully and disposed of according to local and state regulations.