| Chromium Etchants |

CHROMIUM ETCHANT 1020 |

CHROMIUM ETCHANT 1020AC |

Etchants for chromium thin films for microelectronics applications offer excellent compatibility with positive and negative photoresists. Chromium Etchants provide fine-line control with minimal undercutting. High purity formulations filtered to 0.2 micron are ideal for critical devices.

CHROMIUM ETCHANT 1020

Fast etch rate with minimal undercutting

CHROMIUM ETCHANT 1020AC

Slower etch rate to eliminate undercutting and for broader compatibility

CHROMIUM MASK ETCHANT CE-5M

Ideal for high precision photomask etching.

CHROMIUM CERMET ETCHANT TFE

For chromium-silicon films. Compatible with copper, nickel, and gold.

FEATURES:

- High purity

- 0.2 micron filtration

- Excellent photoresist compatibility

- Uniform etch rates and patterns.

Chromium Etchants

1020 and 1020AC

Literature Citations Referencing Application of Chromium Etchant 1020

DESCRIPTION:

Transene Chromium Etchants 1020 and 1020AC are high purity ceric ammonium nitrate systems for precise, clean etching of chromium and chromium oxide films. Chromium Etchant 1020AC is nitric-acid free and exhibits a slower etch rate. Both etchants are compatible with positive and negative photoresists. Chromium Etchant 1020 is filtered to remove all particulates above 0.2 microns. Minimal undercutting is achieved with Chromium Etchant 1020AC.

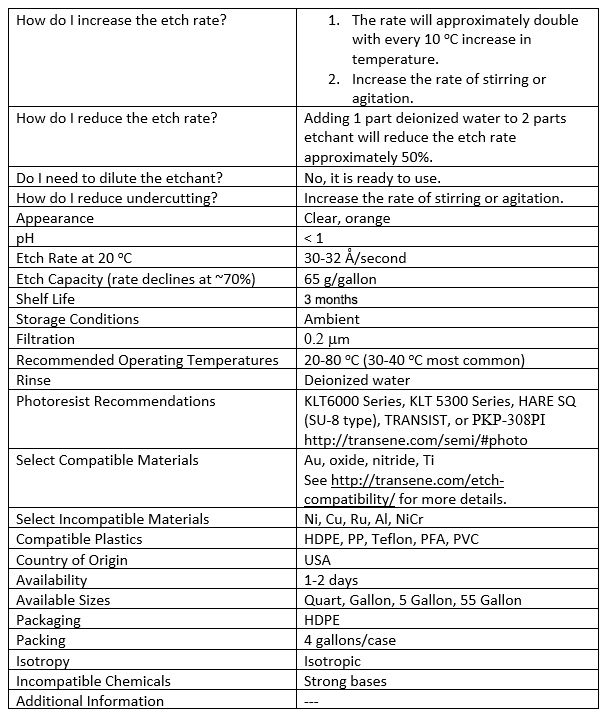

PROPERTIES OF TRANSENE CHROMIUM ETCHANT 1020

| How do I increase the etch rate? | 1. The rate will approximately double with every 10°C increase in temperature. 2. Increase the rate of stirring or agitation. |

| How do I reduce the etch rate? | Adding 1 part deionized water to 2 parts etchant will reduce the etch rate approximately 50%. |

| Do I need to dilute the etchant? | No, it is ready to use. |

| How do I reduce undercutting? | Increase the rate of stirring or agitation. |

| Appearance | Clear orange |

| pH | Acidic |

| Etch Rate at 40°C | 40 Å/sec. |

| Etch Capacity (rate declines at ~70%) | 65 g/gallon |

| Shelf Life | 1 year |

| Storage Conditions | Ambient |

| Filtration | 0.2 um |

| Recommended Operating Temperatures | 20-80oC (30-40oC most common) |

| Rinse | Deionized water |

| Photoresist Recommendations | PKP-308PI or HARE SQ (SU-8 type) |

| Select Compatible Materials | Au, Ti, oxide, nitride, Si

See https://transene.com/etch-compatibility/ for more details. |

| Select Incompatible Materials | Al, Ni, Cu, NiCr |

| Compatible Plastics | HDPE, PP, Teflon, PFA, PVC |

| Country of Origin | USA |

| Availability | 1-2 days |

| Available Sizes | Quart, Gallon, 5 Gallon, 55 Gallon |

| Packaging | HDPE |

| Packing | 4 gallons/case |

| Isotropy | Isotropic |

| Incompatible Chemicals | Strong bases |

| Additional Information | — |

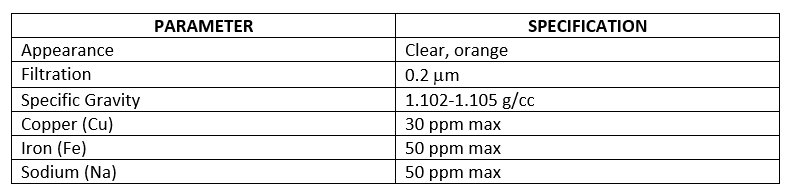

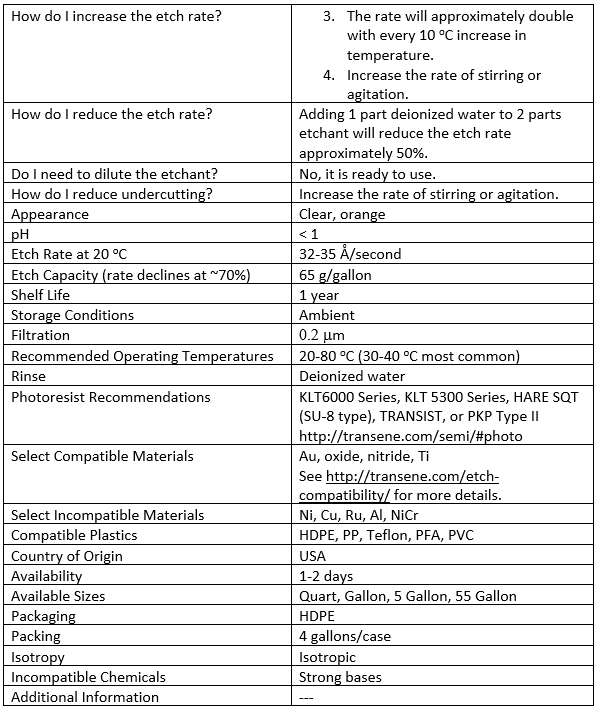

PROPERTIES OF TRANSENE CHROMIUM ETCHANT 1020AC

| How do I increase the etch rate? | 1. The rate will approximately double with every 10°C increase in temperature. 2. Increase the rate of stirring or agitation. |

| How do I reduce the etch rate? | Adding 1 part deionized water to 2 parts etchant will reduce the etch rate approximately 50%. |

| Do I need to dilute the etchant? | No, it is ready to use. |

| How do I reduce undercutting? | Increase the rate of stirring or agitation. |

| Appearance | Clear orange |

| pH | Acidic |

| Etch Rate at 40°C | 32 Å/sec. |

| Etch Capacity (rate declines at ~70%) | 65 g/gallon |

| Shelf Life | 3 months |

| Storage Conditions | Ambient |

| Filtration | 0.2 um |

| Recommended Operating Temperatures | 20-80oC (30-40oC most common) |

| Rinse | Deionized water |

| Photoresist Recommendations | KLT6000 Series, KLT 5300 Series, HARE SQ (SU-8 type), TRANSIST, or PKP-308PI |

| Select Compatible Materials | Au, Ti, oxide, nitride, Si

See https://transene.com/etch-compatibility/ for more details. |

| Select Incompatible Materials | Al, Ni, Cu, NiCr |

| Compatible Plastics | HDPE, PP, Teflon, PFA, PVC |

| Country of Origin | USA |

| Availability | 1-2 days |

| Available Sizes | Quart, Gallon, 5 Gallon, 55 Gallon |

| Packaging | HDPE |

| Packing | 4 gallons/case |

| Isotropy | Isotropic |

| Incompatible Chemicals | Strong bases |

| Additional Information | — |

APPLICATION:

Etching temperature varies depending on film thickness. Etch times range from 15 seconds to 60 seconds at room temperature. Chromium Etchants should be operated in a well ventilated hood.

Chromium Cermet Etchant TFE

DESCRIPTION:

Chromium Cermet Etchant TFE is a selective chromium etchant for microelectronics applications. Chromium Cermet Etchant TFE effectively etches chromium films deposited on copper, nickel, or gold. This potassium hexacyanoferrate formulation is compatible with only negative photoresist. In addition, TFE is an excellent choice for etching chromium oxide, Cr-Si, and Cr-Si-O deposits.

PROPERTIES OF TRANSENE CHROMIUM CERMET ETCHANT TFE

| How do I increase the etch rate? | 1. The rate will approximately double with every 10°C increase in temperature. 2. Increase the rate of stirring or agitation. |

| How do I reduce the etch rate? | Adding 1 part deionized water to 2 parts etchant will reduce the etch rate approximately 50%. |

| Do I need to dilute the etchant? | No, it is ready to use. |

| How do I reduce undercutting? | Increase the rate of stirring or agitation. |

| Appearance | Brown |

| pH | Alkaline |

| Etch Rate at 50°C | 15-20 Å/sec. |

| Etch Capacity (rate declines at ~70%) | 65 g/gallon |

| Shelf Life | 1 year |

| Storage Conditions | Ambient |

| Filtration | 1 um |

| Recommended Operating Temperatures | 20-80oC (30-40oC most common) |

| Rinse | Deionized water |

| Photoresist Recommendations | PKP-308PI or HARE SQ (SU-8 type) |

| Select Compatible Materials | Au, Ni, Cu, alumina

See https://transene.com/etch-compatibility/ for more details. |

| Select Incompatible Materials | Al, Si, Si-O |

| Compatible Plastics | HDPE, PP, Teflon, PFA, PVC |

| Country of Origin | USA |

| Availability | 1-2 days |

| Available Sizes | Quart, Gallon, 5 Gallon, 55 Gallon |

| Packaging | HDPE |

| Packing | 4 gallons/case |

| Isotropy | Isotropic |

| Incompatible Chemicals | Strong acids |

| Additional Information | — |

APPLICATION:

Chromium Cermet Etchant TFE is a ready-to-use solution specifically designed to remove films of Cr, Cr-O, Cr-Si, and Cr-Si-O from metal substrates such as copper, gold, and nickel. Heating the etchant to 40-60 oC will speed the etch rate for thicker films. Continuous stirring is recommended during etching.

Chromium Etchants

For Use in Thin Film Microelectronics.

These etchants are designed for minimal undercutting and good process control. They are compatible with negative and positive photoresists.

Chromium – Types 8001-N and 8002-A

For slower etch rate

8001-N: Nitric acid based

8002-A: Acetic acid based

CHROME ETCHANT CE-8002-A

CE-8002-A Chrome Etchant is a ceric ammonium / acetic acid etching solution for chrome substrates where slower etching rates and no undercutting are preferred. In general, the etch time ranges from 20 to 60 seconds at room temperature (25oC). Contains surfactant.

Storage and Handling:

Store at room temperature away from direct sunlight, keep container sealed when not in use. This is an acid oxidizing solution and should be handled with caution. In case contact is made to eyes or skin, flush with large quantities of water and contact a physician if irritation persists.

SPECIFICATIONS, CE-8002A

CHROME ETCHANTS CE-8001-N, CE-8001-NS

CE-8001-N Chrome Etchant is a ceric ammonium nitrate / nitric acid etching solution for all types of chrome plates. Etch rate will depend upon substrate chrome density and process conditions. In general, the etch time usually ranges from 15 to 55 seconds at room temperature (25oC). The etchant can be supplied with an added surfactant (CE-8001-NS). Chrome Etchant CE-8001-N is suitable for sub-micron photolithography applications.

Storage and Handling:

Store at room temperature away from direct sunlight, keep container sealed when not in use. This is an acid oxidizing solution and should be handled with caution. In case contact is made to eyes or skin, flush with large quantities of water and contact a physician if irritation persists.

Properties

Chromium Cermet Etch – Type TFE

Standard Cr-Si and Cr-SiO Cermets

Etch Rate: 1000 Å/min (for 20 atomic % SiO)

CHROMIUM MASK ETCHANT CE-5M

DESCRIPTION:

Chrome Mask Etchant CE-5M is a ceric ammonium nitrate /perchloric acid etching solution for all types of chrome plates. Etch rate will depend upon substrate chrome density and process conditions. In general, the etch time usually ranges from 15 to 55 seconds at room temperature (25 oC). The etchant can be supplied with an added surfactant (CE-5MS). Chrome Mask Etchant CE-5M is suitable for sub-micron photolithography applications.

Storage and Handling:

Store at room temperature away from direct sunlight, keep container sealed when not in use. This is an acid oxidizing solution and should be handled with caution. In case contact is made to eyes or skin, flush with large quantities of water and contact a physician if irritation persists.

PROPERTIES OF TRANSENE CHROMIUM MASK ETCHANT CE-5M

| How do I increase the etch rate? | 1. The rate will approximately double with every 10°C increase in temperature. 2. Increase the rate of stirring or agitation. |

| How do I reduce the etch rate? | Adding 1 part deionized water to 2 parts etchant will reduce the etch rate approximately 50%. |

| Do I need to dilute the etchant? | No, it is ready to use. |

| How do I reduce undercutting? | Increase the rate of stirring or agitation. |

| Appearance | Clear, orange |

| pH | Acidic |

| Etch Rate at 20°C | 50 Å/sec. |

| Etch Capacity (rate declines at ~70%) | 65 g/gallon |

| Shelf Life | 1 year |

| Storage Conditions | Ambient |

| Filtration | 0.2 um |

| Recommended Operating Temperatures | 20-80oC (30-40oC most common) |

| Rinse | Deionized water |

| Photoresist Recommendations | KLT6000 Series, KLT 5300 Series, HARE SQ (SU-8 type), TRANSIST, or PKP-308PI |

| Select Compatible Materials | Au, oxide, nitride, Ti

See https://transene.com/etch-compatibility/ for more details. |

| Select Incompatible Materials | Ni, Cu, Ru, Al, NiCr |

| Compatible Plastics | HDPE, PP, Teflon, PFA, PVC |

| Country of Origin | USA |

| Availability | Stock item |

| Available Sizes | Quart, Gallon, 5 Gallon, 55 Gallon |

| Packaging | HDPE |

| Packing | 4 gallons/case |

| Isotropy | Isotropic |

| Incompatible Chemicals | Flammables, combustibles, strong bases |

| Additional Information | Oxidizer |

CHROMIUM ETCHANT CRE-473

Chromium Etchant CRE-473 is a selective chromium etchant for plated hard chromium in microelectronics applications. CRE-473 effectively etches plated chromium films deposited on copper, nickel, gold, or molybdenum. Good compatibility with positive and negative photoresists is obtained. CRE-473 is not an effective etchant for sputtered, evaporated, or bulk chromium.

APPLICATION:

Chromium Etchant CRE-473 is a ready-to-use solution specifically designed to remove electroplated chromium films from metal substrates such as copper, gold, nickel, and molybdenum. Heating the etchant to 40 oC will speed the etch rate for thicker films.

PROPERTIES OF TRANSENE CHROMIUM ETCHANT CRE-473

| How do I increase the etch rate? | 1. The rate will approximately double with every 10°C increase in temperature. 2. Increase the rate of stirring or agitation. |

| How do I reduce the etch rate? | Adding 1 part deionized water to 2 parts etchant will reduce the etch rate approximately 50%. |

| Do I need to dilute the etchant? | No, it is ready to use. |

| How do I reduce undercutting? | Increase the rate of stirring or agitation. |

| Appearance | Water-white to light yellow |

| pH | < 1 |

| Etch Rate at 20°C | 14 Å/sec. |

| Etch Capacity (rate declines at ~70%) | 65 g/gallon |

| Shelf Life | 1 year |

| Storage Conditions | Ambient |

| Filtration | 1 um |

| Recommended Operating Temperatures | 20-80oC (30-40oC most common) |

| Rinse | Deionized water |

| Photoresist Recommendations | KLT6000 Series, KLT 5300 Series, HARE SQ (SU-8 type), TRANSIST, or PKP-308PI |

| Select Compatible Materials | Au, oxide, nitride

See https://transene.com/etch-compatibility/ for more details. |

| Select Incompatible Materials | Ni, Al, Ti |

| Compatible Plastics | HDPE, PP, Teflon, PFA, PVC |

| Country of Origin | USA |

| Availability | 1-2 days |

| Available Sizes | Quart, Gallon, 5 Gallon, 55 Gallon |

| Packaging | HDPE |

| Packing | 4 gallons/case |

| Isotropy | Isotropic |

| Incompatible Chemicals | Strong bases |

| Additional Information | — |