Moly Etchant – TFM

|

Moly Etchant – TFM

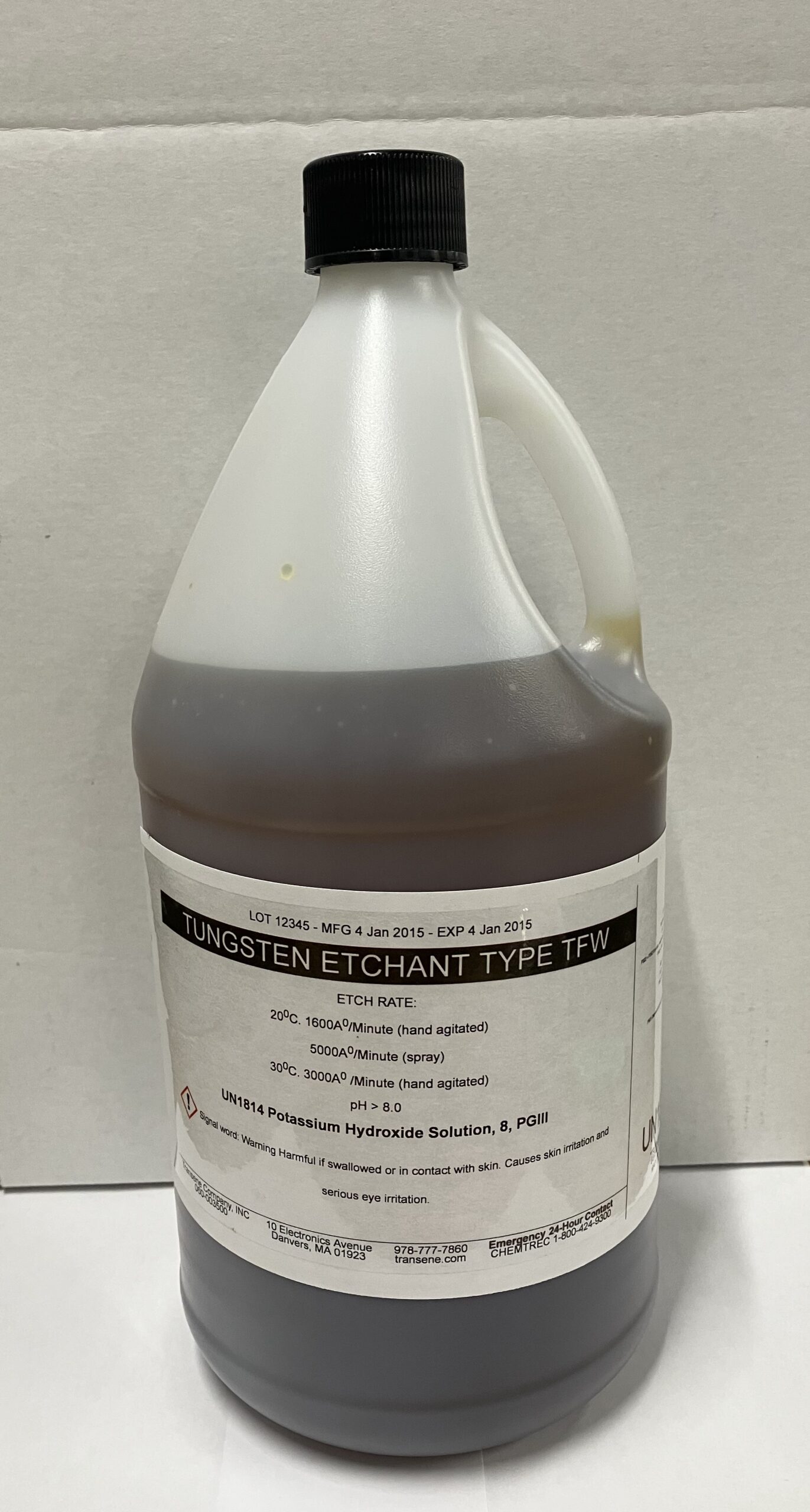

Tungsten Etchant – TFW |

Moly Etchant – TFM

Tungsten Etchant – TFW

Selective etchants for moly and tungsten thin-film metallizations used in semiconductor and microelectronics technology. TFM and TFW are safe, selective etchants are buffered, mildly alkaline ferricyanide-based formulations providing high resolution patterns, with minimal undercutting and negative photoresist compatibility. Controlled uniform etching is achieved by immersion or spray etch technique. Alternatively, Moly Etchant 679 is a positive-resist-compatible blend of phosphoric-acetic-nitric acid with slower etch properties.

PROPERTIES OF TRANSENE MOLY ETCHANT TFM

| How do I increase the etch rate? | 1. The rate will approximately double with every 10°C increase in temperature. 2. Increase the rate of stirring or agitation. |

| How do I reduce the etch rate? | Adding 1 part deionized water to 2 parts etchant will reduce the etch rate approximately 50%. |

| Do I need to dilute the etchant? | No, it is ready to use. |

| How do I reduce undercutting? | Increase the rate of stirring or agitation. |

| Appearance | Brown |

| pH | 10 |

| Etch Rate at 30°C 80°C |

55 Å/sec. 85 Å/sec |

| Etch Capacity (rate declines at ~70%) | 30 g/gallon |

| Shelf Life | 1 year |

| Storage Conditions | Ambient |

| Filtration | 1 um |

| Recommended Operating Temperatures | 20-80oC (30-40oC most common) |

| Rinse | Deionized water |

| Photoresist Recommendations | PKP-308PI or HARE SQ (SU-8 type) |

| Select Compatible Materials | Au, Ni, Cu, alumina

See https://transene.com/etch-compatibility/ for more details. |

| Select Incompatible Materials | Al, Si, Si-O |

| Compatible Plastics | HDPE, PP, Teflon, PFA, PVC |

| Country of Origin | USA |

| Availability | 1-2 days |

| Available Sizes | Quart, Gallon, 5 Gallon, 55 Gallon |

| Packaging | HDPE |

| Packing | 4 gallons/case |

| Isotropy | Isotropic |

| Incompatible Chemicals | Strong acids |

| Additional Information | — |

PROPERTIES OF TRANSENE TUNGSTEN ETCHANT TFW

| How do I increase the etch rate? | 1. The rate will approximately double with every 10°C increase in temperature. 2. Increase the rate of stirring or agitation. |

| How do I reduce the etch rate? | Adding 1 part deionized water to 2 parts etchant will reduce the etch rate approximately 50%. |

| Do I need to dilute the etchant? | No, it is ready to use. |

| How do I reduce undercutting? | Increase the rate of stirring or agitation. |

| Appearance | Brown |

| pH | 8 |

| Etch Rate at 20°C | 30 Å/second (immersion)

80 Å/second (spray) |

| Etch Capacity (rate declines at ~70%) | 64 g/gallon |

| Shelf Life | 1 year |

| Storage Conditions | Ambient |

| Filtration | 1 um |

| Recommended Operating Temperatures | 20-80oC (30-40oC most common) |

| Rinse | Deionized water |

| Photoresist Recommendations | PKP-308PI or HARE SQ (SU-8 type) |

| Select Compatible Materials | Au, Ni, Cu, alumina

See https://transene.com/etch-compatibility/ for more details. |

| Select Incompatible Materials | Al, Si, Si-O |

| Compatible Plastics | HDPE, PP, Teflon, PFA, PVC |

| Country of Origin | USA |

| Availability | 1-2 days |

| Available Sizes | Quart, Gallon, 5 Gallon, 55 Gallon |

| Packaging | HDPE |

| Packing | 4 gallons/case |

| Isotropy | Isotropic |

| Incompatible Chemicals | Strong acids |

| Additional Information | — |