TRANSIST PHOTORESIST PRODUCTS

DESCRIPTION

Transene is pleased to introduce a new line of products for photolithography. Featuring excellent compatibility with most wet etchants, the TRANSIST series of photoresist products provides a dependable, high-resolution solution for microelectronic applications. Available as either positive or negative working photosensitive resists, TRANSIST offers a low-toxicity alternative designed for use with Transene etchants.

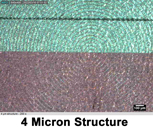

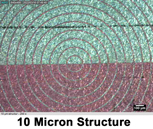

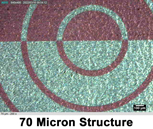

TRANSIST NC500 and ND560 are negative photoresists suitable for either spin coating or dip coating applications. With sensitivity in the absorbance range 300-450 nm, TRANSIST NC500 and ND560 will resolve patterns as precise as 1 micron, depending on the processing conditions. The dried polymers exhibit excellent substrate adhesion.

TRANSIST NC500 and ND560 are available individually or in a kit with developer, rinse, stripper, and thinner.

TRANSIST PC800 and PD860 are high-resolution positive working photoresists with superior substrate adhesion. Developing in the 300-450 nm range, TRANSIST PC800 and PD860 are stable in most acid etching media and are suitable for dip coating or spin-on applications. TRANSIST PC800 and PD860 are ideal for use in standard wet etch tooling.

TRANSIST PC800 and PD860 may be purchased individually or in a kit with developer, rinse, stripper, and thinner.

PROPERTIES OF TRANSIST PHOTORESISTS

| Property | NC500 | ND560 | PC800 | PD860 |

| TYPE | NEGATIVE | NEGATIVE | POSITIVE | POSITIVE |

| COLOR | RED | RED | YELLOW | YELLOW |

| VISCOSITY @ 23 °C | 425 cps | ~45 cps | 100 cps | 80 cps |

| SOLIDS % | 35 | 20 | 35 | 20 |

| ABSORBANCE RANGE | 300-410 nm | 300-410 nm | 300-450 nm | 300-450 nm |

| DENSITY | 1.015 g/cc | 1.01 g/cc | 1.045 g/cc | 1.03 g/cc |

| TYPICAL THICKNESS | 3-10 ų | 1-3 ų | 3-10 ų | 1-3 ų |

| STORAGE | Ambient | Ambient | 8°C | 8°C |

| SHELF LIFE | 1 YEAR | 1 YEAR | 1 YEAR | 1 YEAR |

TRANSIST PROCESSING CHEMICALS

| PROCESSING CHEMICAL | TRANSIST NC500 | TRANSIST ND560 | TRANSIST PC800 | TRANSIST PD860 |

| DEVELOPER | NC1500 | ND1560 | PC1800 | PD1860 |

| RINSE | NC2500 | ND2560 | PC2800 | PD2860 |

| STRIPPER | NC3500 | ND3560 | PC3800 | PD3860 |

| THINNER | NC4500 | ND4560 | PC4800 | PD4860 |

TRANSIST NC500 and ND560 PROCESSING PARAMETERS

SURFACE PREPARATION

The substrate should be clean and free of debris. Employ a cleaning solution suitable for the substrate. Transene 100, for example, leaves a clean, residue-free surface. Visit www.transene.com/cleaning/#100 for more information.

COATING

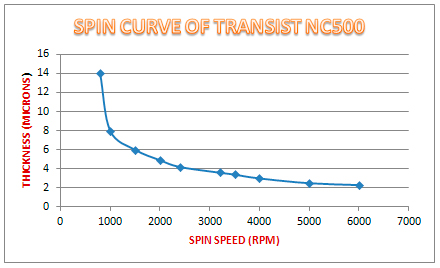

Undiluted TRANSIST NC500 may be applied via dip coating or spin coating. In a spin coating application, a spin speed of 1500-4000 rpm with a 100 rpm ramp up is recommended. Under these conditions, dry resist thickness in the 3-6 micrometer range is obtained. Coating quality is independent of spin speeds within the recommended range.

For higher resolution and thinner resist deposition, TRANSIST ND560 may be substituted. At similar rotation speeds, dry resist coatings in the range of 1-3 microns are obtained.

Alternatively, TRANSIST NC500 and ND560 may be dip coated either manually or using automated equipment for optimum uniformity. Coating thickness distribution of +/- 10% is attainable at thicknesses from 1-10 micrometers using this method.

Thinner NC4500 may be used to dilute TRANSIST NC500, and Thinner ND4560 is appropriate for use with TRANSIST ND560.

Undiluted TRANSIST PC800 is a positive working resist which may be applied via dip coating or spin coating. In a spin coating application, a spin speed of 1500-4000 rpm with a 100 rpm ramp up is recommended. Under these conditions, dry resist thickness in the 3-6 micrometer range is obtained. Coating quality is independent of spin speeds within the recommended range.

For higher resolution and thinner resist deposition, TRANSIST PD860 may be substituted. At similar rotation speeds, dry resist coatings in the range of 1-3 microns are obtained.

Alternatively, TRANSIST PC800 and PD860 may be dip coated either manually or using automated equipment for optimum uniformity. Coating thickness distribution of +/- 10% is attainable at thicknesses from 1-10 micrometers using this method. Thinner PC4800 may be used to dilute TRANSIST PC800, and Thinner PD4860 is appropriate for use with TRANSIST PD860.

DRYING

The coated resist will dry to a tack-free state under exposure to low speed, filtered air flow within five minutes. Air drying is followed by a ten minute dwell time in a convection oven at 80 oC. The oven drying step is required for subsequent processing. Avoid drying temperatures above 100 oC which might lead to unacceptable surface quality. No post-drying hold time is required. Coated, dried parts may be held for up to 24 hours in a cleanroom environment. Alternatively, the part may be dried for ten minutes on a hot plate.

EXPOSURE

After drying, the resist may be exposed to collimated light between 300 and 450 nm, ideally 350-400 nm. An exposure energy of 200-400 mJ/cm2 is recommended, resulting in a step wedge reading of approximately 4-6 solid.

A post-exposure hardbake is not normally required but may be implemented for added post-processing chemical resistance.

DEVELOPING

TRANSIST NC500 may be developed using Developer NC1500. Unexposed areas of the resist will normally dissolve in 45-90 seconds at 25 oC, but raising the developer temperature will accelerate the process and assist in dissolving difficult-to-remove coatings. Excessive heating or overly long exposures may also damage the polymerized resist. The development process is quenched by immersion in Rinse NC2500 for 5-10 seconds followed by a deionized water rinse.

Similar processing conditions should be used when developing TRANSIST ND560 using Developer ND1560. Post-developing, immerse the part in Rinse ND2560 for 5-10 seconds to arrest the development process. Finally, rinse in deionized water.

Once the photoresist has been developed, it is ready for additional processing either in acidic plating or acidic wet etching chemistries. TRANSIST NC500 and ND560 are not suitable for alkaline plating or etching environments. In such situations, PKP II Photoresist is preferred. www.transene.com/pkp/

STRIPPING

Stripper NC3500 is designed for rapid removal of TRANSIST NC500 at temperatures of 50 oC or greater. This alkaline stripper will induce the resist to peel away in flakes. Agitation of the stripper during this process is recommended. For TRANSIST ND560, Stripper ND3560 may be used under similar conditions.

TRANSIST PC800 and PD860 PROCESSING PARAMETERS

SURFACE PREPARATION

The substrate should be clean and free of debris. Employ a cleaning solution suitable for the substrate. Transene 100, for example, leaves a clean, residue-free surface. Visit www.transene.com/cleaning/#100 for more information.

DRYING

The coated resist will dry to a tack-free state after exposure to low velocity, filtered air flow for 1-3 minutes. Air drying is followed by a ten minute dwell time in a convection oven at 80 oC. The oven drying step is required for subsequent processing. Avoid drying temperatures above 100 oC which might lead to poor surface quality. No post-drying hold time is required. Coated, dried parts may be retained for up to 24 hours under cleanroom conditions. Alternatively, the part may be dried for ten minutes on a hot plate.

EXPOSURE

After drying, the resist may be exposed to collimated light between 300 and 450 nm, ideally 350-400 nm. An exposure energy of 200-350 mJ/cm2 is ideal, resulting in a step wedge reading of approximately 1-3 solid. Avoid long exposure times that may overheat the resist.

DEVELOPING

TRANSIST PC800 may be developed using Developer PC1800. Unexposed areas of the resist will normally dissolve in 30-45 seconds at 20-30 oC, but raising the developer temperature will accelerate the process or allow processing of difficult-to-remove coatings. Excessive heating or excessively long exposures may also damage the polymerized resist. The development process must be quenched by immersing the substrate in Rinse PC2800 for 5-10 seconds followed by a rinse in deionized water.

Similar processing conditions should be used when developing TRANSIST PD860 using Developer PD1860. Post-developing, immerse the part in Rinse PD2860 for 5-10 seconds to arrest the development process. Finally, rinse in deionized water.

Once the photoresist has been developed, it is ready for additional processing either in acidic plating or acidic wet etching chemistries. TRANSIST PC800 and PD860 are not suitable for alkaline plating or etching environments. In such situations, PKP II Photoresist should be employed. www.transene.com/pkp/

STRIPPING

Stripper PD3800 is designed for rapid removal of TRANSIST PC800 at temperatures of 50 oC or greater. This alkaline stripper will induce the resist to peel away in flakes. Agitation of the stripper during this process is recommended.

For TRANSIST PC860, Stripper PD3860 may be substituted under similar conditions.